Equipment

Equipment You Can Rely On

Whether you need the most reliable pelleting equipment or want to reduce energy and floor space in your can-handling line, we have what it takes to optimize your operation every step of the way.

Pelleting, Size Reduction, & Briquetting

We’ve united the brands our customers trust to produce advanced, durable equipment that won’t quit. Whether it’s briquetting, grinding, pelleting, rolling, crushing, or anything else, our machines will get it done with unbeatable efficiency and reliability.

Pelleting Systems

Whether it’s pounds of pellets per hour or tons of pellets per hour, you can depend on our equipment to meet your specific requirements. Our pellet systems equipment can help you upgrade your pellet-making process to the next level:

- Pellet Mills: easier, safer, and more efficient. You won’t find a better pellet machine anywhere.

- Pellet Crumblers: high-capacity, high-efficiency machines proven to produce continuously even crumbs, even in the most challenging conditions.

- Conditioners: market-leading conditioners that give you maximum performance and flexible configuration specific to the materials you’re pelleting.

- Coolers: designed to occupy minimal floor space, our coolers offer the greatest process efficiency functions and ease of operation, giving you big results with a small footprint.

- Sifters and Cleaners: our gyro sifter and feed cleaner is a modern version of our iconic whirly feed cleaner and is designed to protect your downstream equipment and product quality.

Size Reduction

Take your particle size control to the next level. Whether it’s grinding, crushing, or flaking, you can count on our equipment lineup to handle even the toughest applications:

- Hammermills: Rugged and highly efficient, our hammermills are used in an extensive variety of applications, including wood, oilseeds, and pet food.

- Roller Mills & Roll Crushers: Masters of the daily grind, our machines deliver consistent, uniform, and precise particle size control.

- Lump Breakers & Crushers: Our equipment reduces deliberately compacted materials as well as natural lumps that occur during production, storage, or transportation.

- Flaking Mills: Our high-capacity, high-efficiency and low operating cost flaking machines offer consistently uniform flakes every time.

- Cracking Mills: Used to break stock into smaller pieces, our equipment is known worldwide for high-capacity, consistent, and trouble-free performance.

- Feeders: Our full range of roll, rotary, and screw feeders, air separators, and magnet adapters ensures consistent product flow to your equipment.

- Steam Chambers: Our chambers are flexibly designed and sized to fit your specific steam-flaking application. Our unique steam inlet means uniform flow and low-velocity, high-volume steam addition.

Briquetting Presses

Create sustainable value from wood and industrial waste. With our briquetting presses, you can compact your waste or recycle the byproduct into high-density briquettes. These briquettes can be sustainably re-used as material in other processes or stored for reduced disposal cost:

- Mechanical Briquetting: High-pressure mechanical presses are designed to meet the requirements of customers that need to compact large quantities of waste or fiber.

- Hydraulic Briquetting: Our presses can recover almost all of the coolant contained in metal sludge and swarf. The resulting briquettes can be easily handled, transported, or recycled.

Temperature & Moisture Control

We offer the best high-capacity thermal processing equipment designed specifically for the unique needs of the food, chemical, and fiber industries. Our range of products is designed and built specifically for your operation, giving you efficiency, reliable output, and longevity of operations.

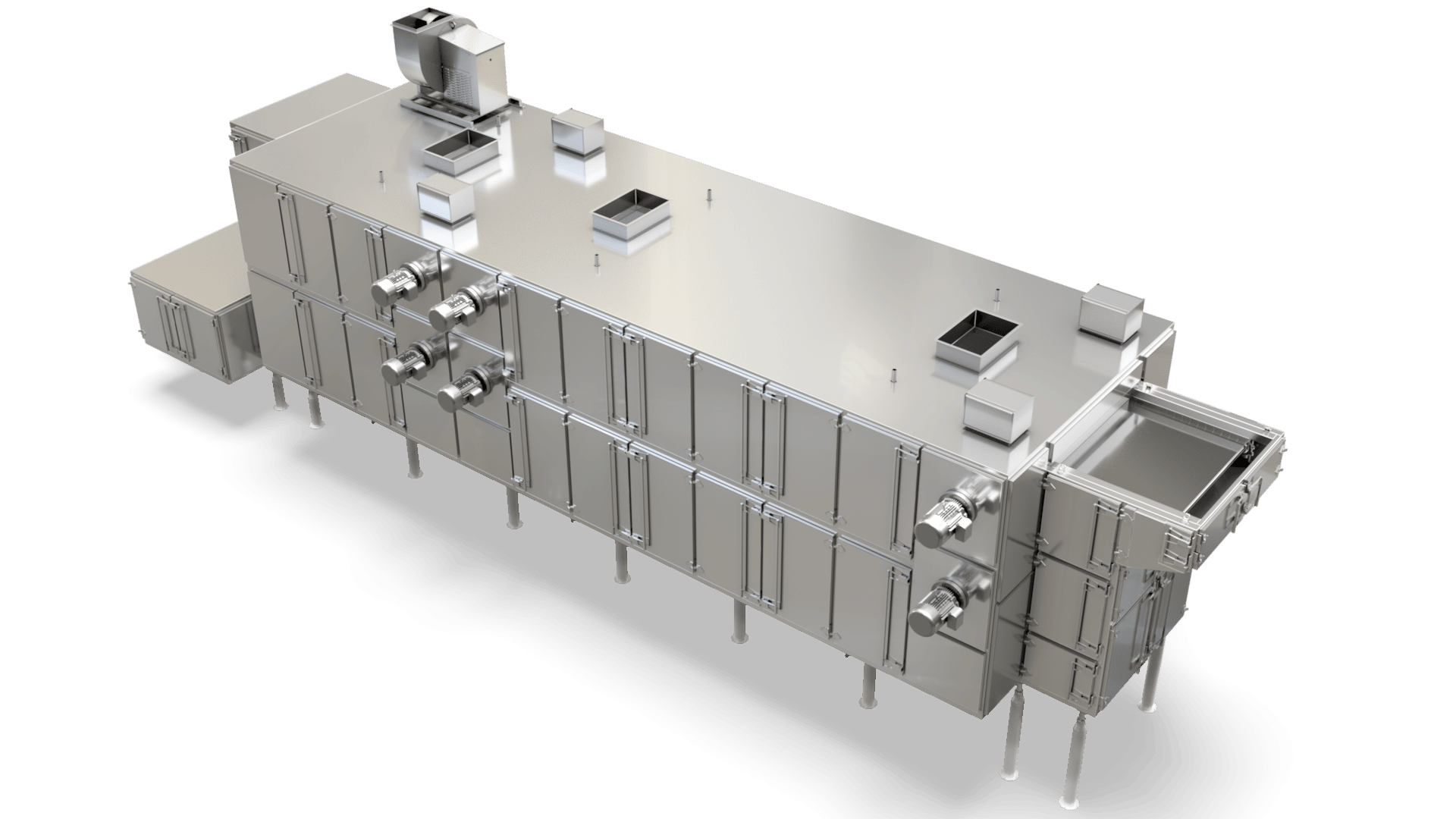

Dryers

Hard-to-dry products, meet your match. If you want maximum uniformity in your drying process, we have the machinery for you, no matter your need or floorspace. We engineer our time-tested equipment for efficiency and innovation in airflows, materials, and customization. Whether it’s a two-foot-wide (0.6m) unit drying an expensive pharmaceutical product or a 14-foot-6-inch wide (4.4m) machine producing product at a rate of 100,000 pounds per shift, our components and configurations are reliably engineered to meet your production requirements.

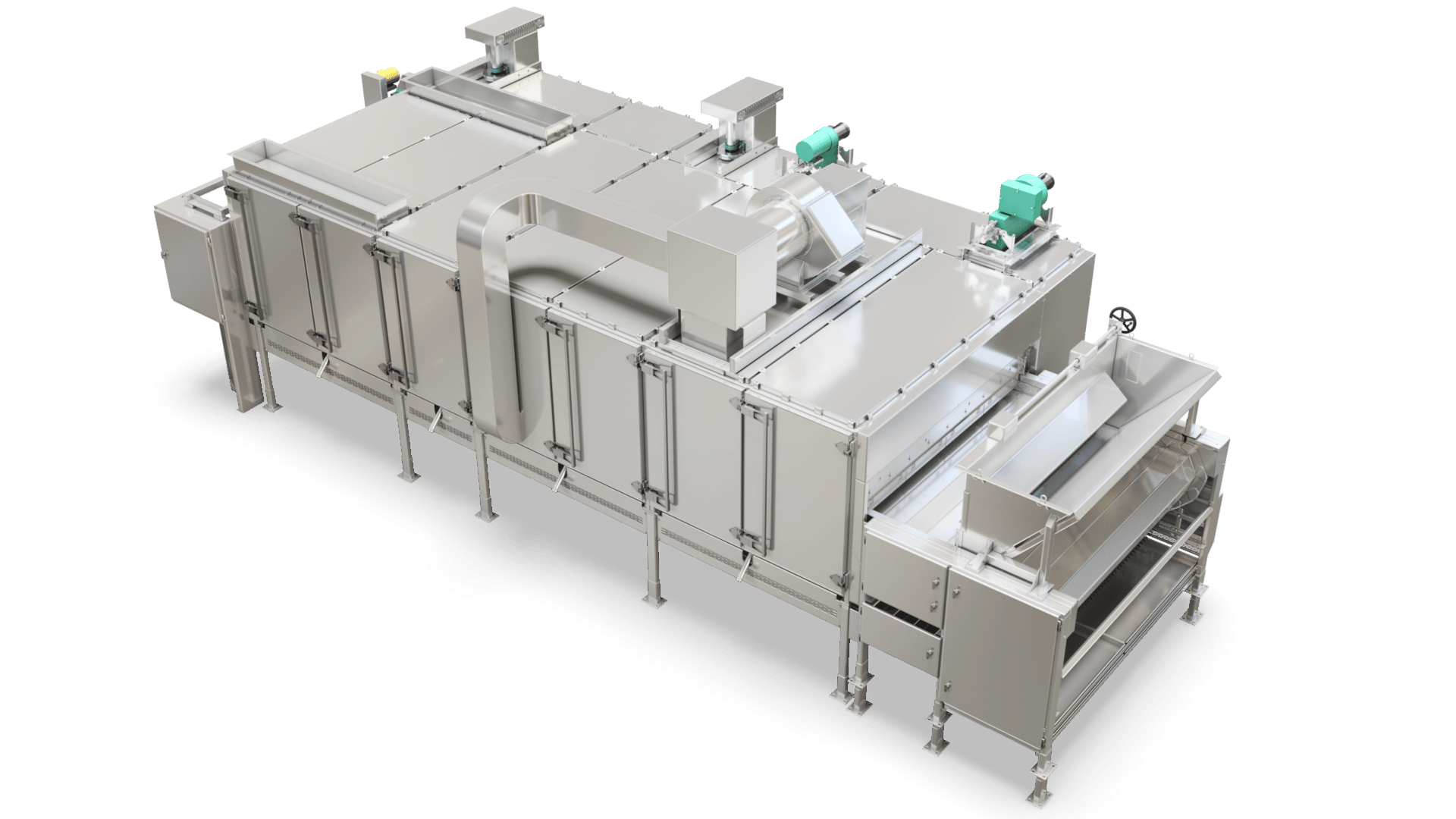

Roasters/Coolers

Our nut and seed roaster/cooler range is the established benchmark in the nut industry. Its proven design brings rugged efficiency to any nut processing line. From roasted peanuts to hazelnuts to various coated nuts, our machines excel. Our equipment can meet virtually all of your roasting and cooling requirements, including for specialty products such as chicory and carob.

Puffers

To create the highest performing puffers in the world, we had to invent something new. Our revolutionary Jetzone technology is used in all of our puffers to handle a wide variety of food, chemical, and fiber products. Jet-tube fluidization is the fastest, most uniform, and most efficient method of cooling the majority of particulate free-flowing products. Our machines are engineered to minimize product loss and maximize efficiency.

Toasters

You can trust our patented technology with any toasting demand. We offer a range of toasters that can handle any food, chemical, or fiber product. All of our machinery is engineered for maximum efficiency, no matter the space or specification. Built for unmatched ease of use, our toasters offer complete control of zone air flow, temperature, humidity, exhaust, and conveyor speed. Our toasters are engineered with a modular design to allow for easy future expansion and minimal installation time.

Ovens

Turn up the heat on your food processing operation. Our advanced ovens are engineered to efficiently create the best result for any cooked product. We have an option for any size of industrial cooking process and the versatility for any demand. Built with efficiency in mind, our ovens create temperature uniformity to meet any of your product toasting needs. The advanced jet air circulation system used in our ovens allows the use of alternate fuels, enabling your whole operation to be more environmentally friendly.

Grills & Griddles

Keep your customers coming back. Our grills deliver an unbeatable taste on an industrial scale to all of your fully cooked products, while our griddles deliver perfect pancakes, waffles, and French toast. We have a range of grills and griddles to meet any demand, and our equipment is configured to your specific process, optimizing your efficiency and ensuring high-quality output and uniformity.

Extruders

We have decades of experience in the development of extrusion systems. Our extruders cover all kinds of applications, compounding systems, and supporting technologies. From entry-level to high-level specifications and from new equipment to spare parts, our extruders are built to handle any of your process needs.

Ring Extruder

Built with revolutionary technology, you can rely on our RingExtruder RE® to continuously and efficiently process temperature-sensitive materials. The innovative composition of our RingExtruder RE technology is based on 12 screw shafts, which reduce barrel and screw wear, allowing increasing reliability and maximizing the product life cycle. Our RingExtruders RE are perfect for environmentally friendly applications, such as rubber compounding for high-performance Green Tires and degassing of post-consumer PET bottles in bottle-to-bottle recycling.

Twin-Screw Extruder

We’ve innovated our twin-screw extruders to add unmatched performance and reliability to your manufacturing process. Built with the highest quality materials, with a focus on reliability and adaptability, our series of twin-screw extruders offer robust solutions to meet the needs of any operation. Globally recognized for high quality, low maintenance, and outstanding customer service, our twin-screw extruders are the industry benchmark.

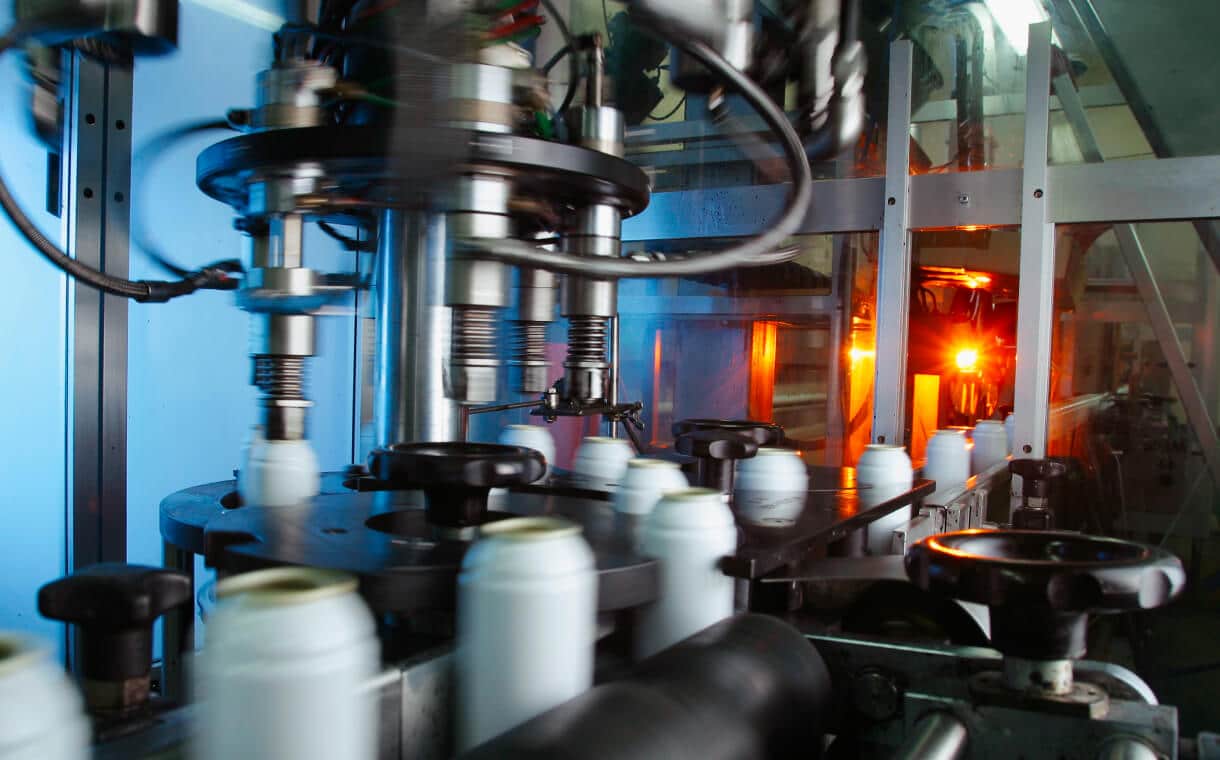

Can Handling

When it comes to can handling, we can handle it. From washers and dryers to conveyor belt systems, our products are built with a focus on sustainability. We have innovative can handling solutions for every step in your line.

Can Washers

Can Dryers

Our can dryers are optimized for reliability and efficiency to reduce energy costs during the can drying process. With a focus on speed and ease of use, our drying systems eliminate all moisture from cans to prepare them for perfect decoration and presentation. Our can dryers have become so well-known for their minimization of required energy and floorspace, they serve as the industry standard for can drying equipment.

Can Ovens

Innovated for high speed and efficiency, our can ovens are designed to ensure the most effective application of coatings and finishes onto steel and aluminum cans. All of our ovens are built with the highest quality in mind to ensure ease of use and reliability. With an eye on making our machinery as environmentally friendly as possible, we’ve engineered our can ovens to minimize spillage, which reduces overall costs and energy consumption.

Conveyor Systems

Improve efficiency and speed at any point in your can handling process with our conveyor systems. From spare parts to entire handling systems, we provide a comprehensive product portfolio to meet any conveying demands. With a commitment to efficiency and ease of use, we’ve designed our conveyors to easily integrate into any pre-existing operation. Additionally, our team of experts can get you set up if you’re starting a conveying process from scratch.

Start the Conversation with Us

Get in touch with one of our team members to learn more about how we can optimize your operation.

Get in touch

Let’s Feed, Fuel, and Build a Better World Together

Learn how we help advance productivity, achieve cost savings, and deliver solutions for customers.