That’s why it’s not unusual for our aftermarket and support teams to be working on, and providing support and parts for CPM equipment that’s 40, 60 or even 80+ years old.

We work hard to embrace sustainable manufacturing systems in all the equipment we make. But sometimes the most significant sustainability benefits come from keeping an existing piece of equipment running for the long haul.

Our Oldest Running Pellet-Mills

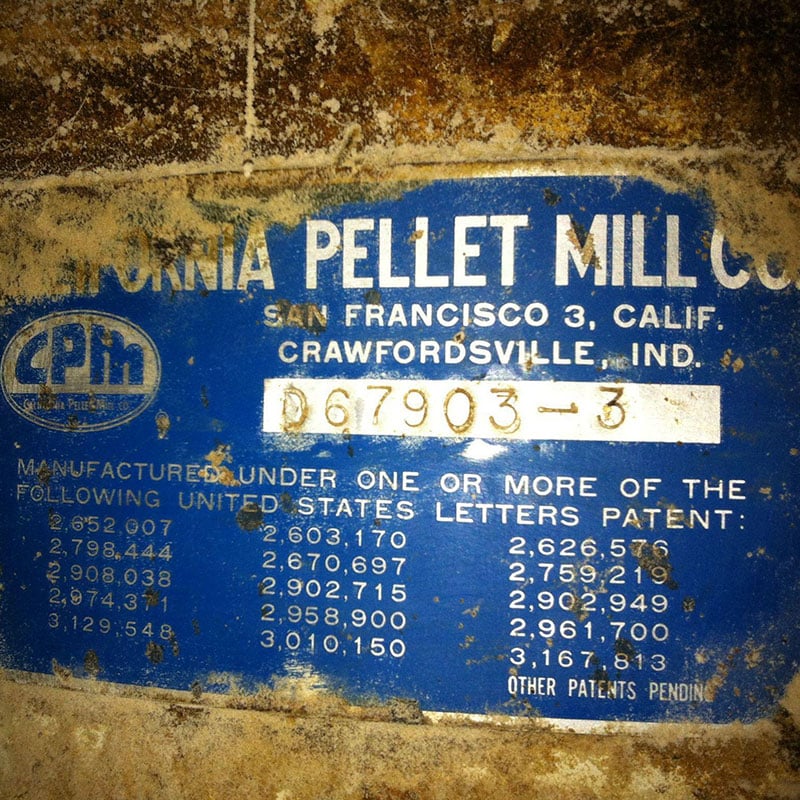

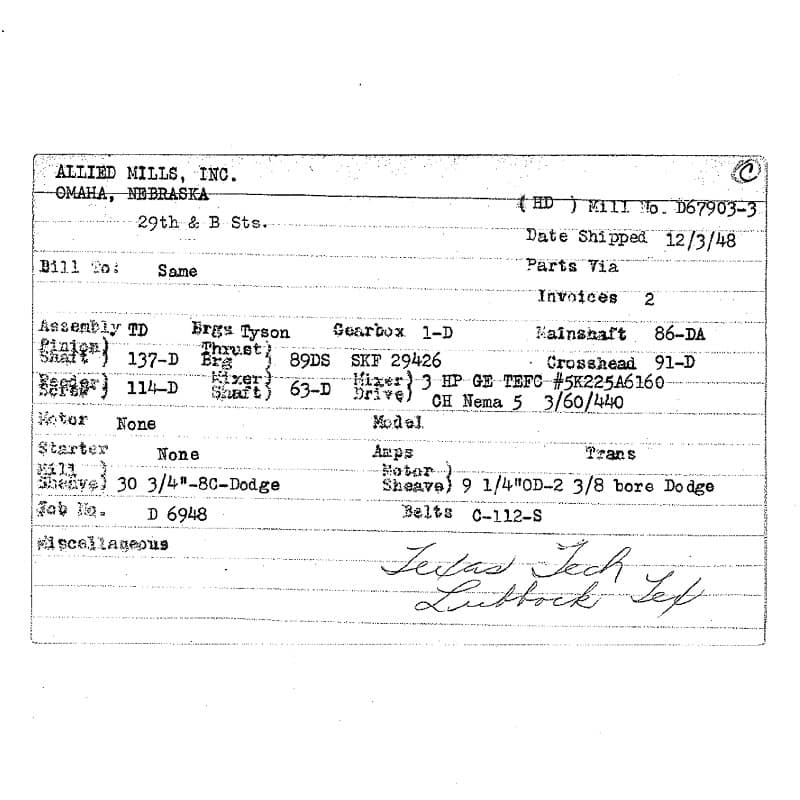

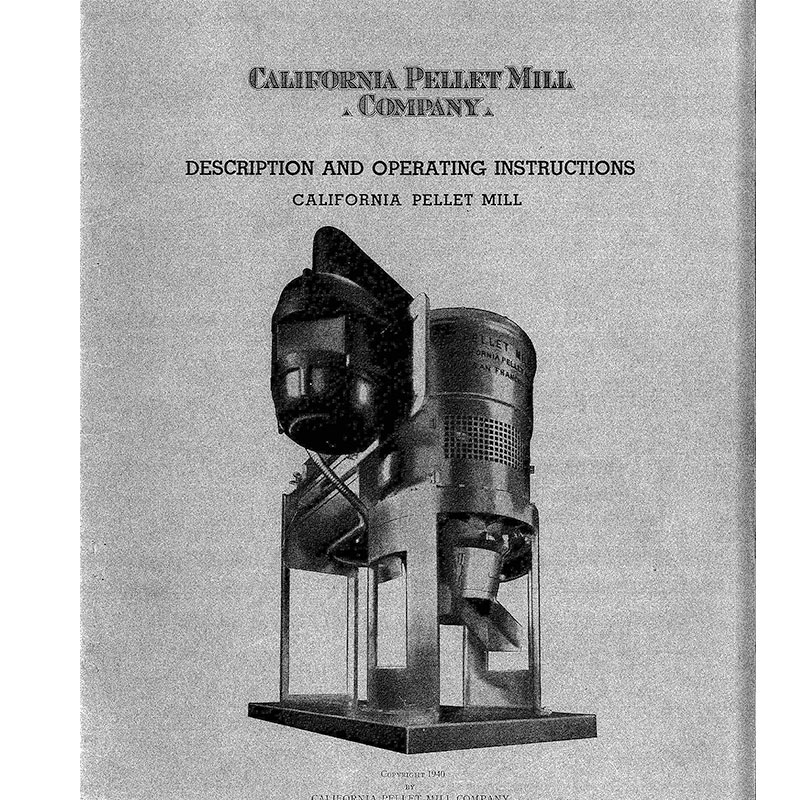

The oldest-running CPM pellet mills we know of and are still providing aftermarket support for are currently operating in Cisco, Texas. We have documentation for the original sale of the newer unit, which was sold in 1948. We suspect the older unit was put into service around 1945.

The units were originally sold to Allied Mills in Omaha, Nebraska, then later transferred to Texas Tech University, and later to another private company in Texas.

Most recently, CPM’s aftermarket team provided parts for these units in 2022, and we’ve been continually supporting them for more than 75 years of operation.

Decades of Dryers

When Blair Thompson joined CPM product brand Wolverine Proctor in 1990, he was joining a company where his father had enjoyed a 45-year career. Today, Blair is an Aftermarket Sales Manager, Process Solutions where he has more than three decades of experience supporting the company’s Wolverine Proctor-branded drying equipment.

New Machines from the Boneyard

One of Blair’s first big projects with CPM’s Wolverine Proctor happened in 1992 when he got a call from an industrial pigment manufacturer in Pennsylvania. The company had changed ownership, and the new owners found several disused and poorly maintained Wolverine Proctor dryers units from the 1960s and 1970s sitting out in the elements behind their factory.

The new owners were familiar with Wolverine Proctor’s reputation for quality and durability, so they called Blair and his team to come in, and see if it’d be possible to assemble the old parts into a functional machine.

While Blair and his team were skeptical, when they arrived, they found that the discarded machines had enough good parts to rebuild into a functional unit. They told the client they could do it, found the best component parts, rebuilt a few pieces, added new conveyors and delivered the client a “brand new” 30+ year old machine.

That dryer is still operating today, more than 50-years after the manufacture of the original parts, and 30-years after its re-assembly and update by Blair and his team.

Generations of Support

Many of the older Wolverine Proctor machines that Blair and his team support were originally sold by Blair’s father. Between 1974 and 1978, Blair’s father sold a fleet of 50 industrial dryers to a major pet food manufacturer that were commissioned across six different locations.

In 2004, that manufacturer asked CPM’s aftermarket and service team to collaborate with them on an efficiency audit, which would look for ways to implement efficiency improvements in their dryers. Together with the customer’s engineering team, CPM identified key opportunities for energy-efficient modernizations that centered around more efficient fans and steam coils. Over the next five years, CPM’s aftermarket and service team implemented the upgrades across the client’s array of dryers.

Today, they’re still in operation, 50 years after they were originally sold and put into service by Blair’s father, and close to two-decades after the energy-efficiency upgrades implemented by Blair and his team.

Long-Lasting Pellet Mills in Latin America

Around the world, CPM pellet mills are known for their promise to “just run.”

“The machines keep working,” said Evandro Magnus, Managing Director, South America, Industrial Solutions. “The longevity of CPM equipment makes it absolutely necessary to have robust and complete aftermarket solutions and services.”

As technology advances, CPM pellet mill models have been introduced and retired over the company’s 100+ year history. In 1985, CPM stopped manufacturing its Century pellet mill product line when it was replaced by the 3000 Series product line. Yet today, CPM Latin America is supporting more than 230 Century pellet mills in active operation, all of which are a minimum of 39 years old.

“Just this morning, I was working on an upgrade package for Century in Trinidad,” said Gerry Maroulis, Sales Manager, Latin America, Industrial Solutions. “It’s a machine that’s been running for 24/7 for close to 50 years.

The Keys to Longevity

Gerry, Evandro and Blair all agree on a few key factors that contribute to the long life of CPM equipment.

The first is equipment that’s engineered, and built to last.

“It’s a combination of craftsmanship, heavy-duty construction, performance and simplicity in design,” said Gerry. “Maintenance people love our machines, and operators love them too.”

Another factor is CPM’s legacy documentation and experience.

“We’ve got more than a century of records at Wolverine Proctor. Back in the 1970s, my predecessors stored all their historical documentation on microfiche,” said Blair. “Now we’ve digitized all that, and everything going forward.”

Gerry agrees.

“If we can get a serial number, we’ll have accurate documentation on that machine going back into the 1940s.”

That documentation helps CPM’s aftermarket support team efficiently maintain, upgrade and modernize older equipment.

Another critical factor is a commitment to long-term support.

“Our reputation is for offering the best support in the industry,” said Evandro. “We regularly support 70-year-old machines.”

Part of that support comes in the form of experienced field technicians who can be on-site in a matter of hours or days anywhere around the globe. Another part comes in the form of a commitment to stocking parts and supplies for decades worth of equipment.

CPM’s global OneCPM model also offers real support advantages.

“We keep commonly-needed parts and supplies here locally,” said Evandro, “but if we need something unusual, I can source it from my CPM colleagues in North America, Europe or Asia if I don’t have it.”

Finally, the long lifespan of much of CPM’s equipment is tied to the company’s ability to upgrade and modernize older equipment. Whether it’s efficiency upgrades like the ones Blair performed on machines sold by his father, increases in capacity, or the implementation of advanced automation techniques, CPM equipment owners have a whole host of options to bring their older equipment inline with modern standards.

Take Advantage of Equipment that Lasts

Whether you’re interested in equipment that lasts for a decade, or a century, you can trust CPM for equipment that’s built to last. Contact us today to find the equipment that meets your needs now, and in the future.