SKZ and CPM continued their longstanding relationship.

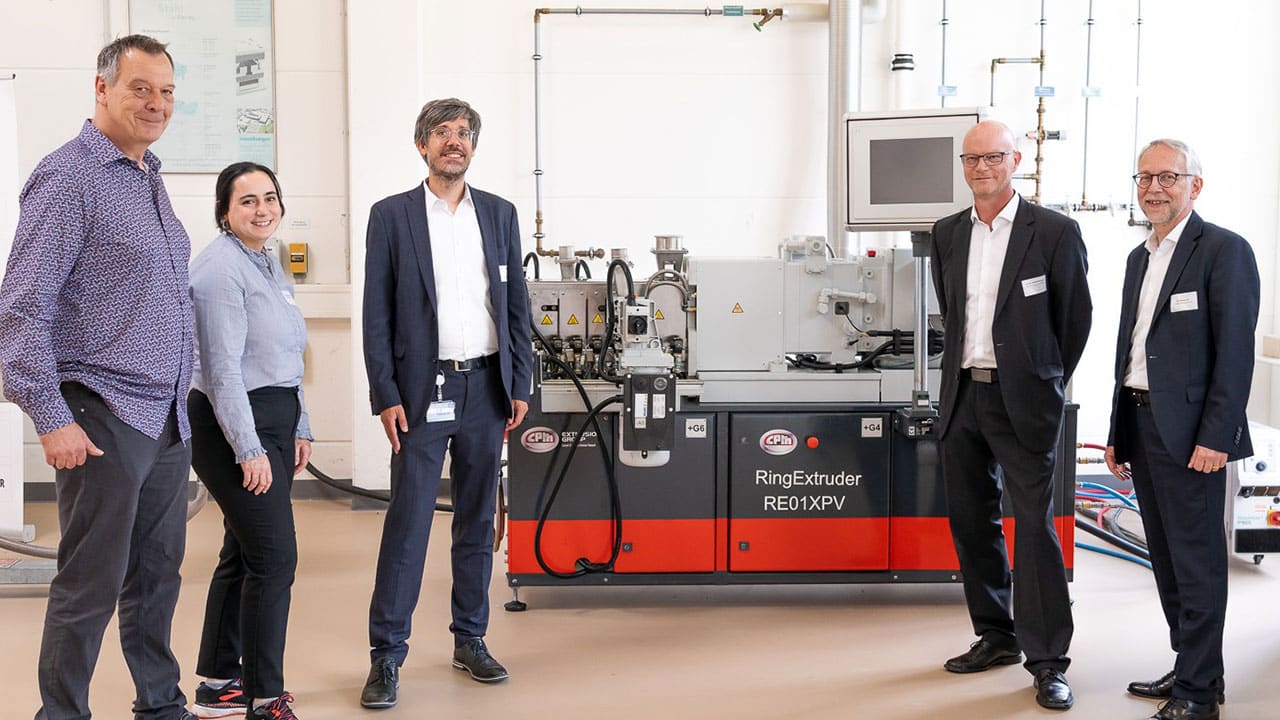

CPM installed a new RingExtruder at the Plastics Center in Würzburg, Germany.

The extruder from CPM (Extricom Extrusion GmbH,) equipped with 12 screws, expands the already extensive technical equipment of various single and multi-screw extruders at the SKZ.

RingExtruders produce a good dispersing effect due to high proportions of extensional flow. Comparably small screw diameters can reduce the shear and pressure peaks in the material with an even input of energy. This allows efficient and gentle compounding. At the same time, a large surface area is available for heat exchange with the barrel and core of the extruder. A very good degassing capability is also an advantage of the RingExtruder, which is why the technology is often used in recycling, for example when hydrolysis-sensitive PET flakes are used. The 12 screws offer the further advantage that spreading forces are minimized. This helps reduce scroll and barrel wear.

The SKZ has experience with an older RingExtruder and the research team is already looking forward to exhausting the possibilities on a new system and finding new areas of application.

“We already have initial ideas for some research projects. An improvement in process understanding is certainly of great interest, especially for industrial users. This work then provides the basis for application-oriented process developments,” explained Hatice Malatyali, Group Manager Extrusion and Compounding at SKZ.

“The advantages of the RingExtruder hold great potential, especially in the recycling and processing of biopolymers. We are therefore very excited about initial inquiries from the industry, as we naturally prefer to research practical applications.”

In addition to the rest of the machinery, the RingExtruder is of course also available for compounding requests for sample quantities.

“We would like to thank our member company Extricom Extrusion GmbH, part of the CPM Group, for the opportunity to expand our equipment again and look forward to advancing the knowledge of RingExtruders for the industry,” said Johannes Rudloff, Head of Material Development, Compounding & Extrusion at SKZ.

The two companies have worked together for decades, and Joerg Mayer-Lutz, Project Manager Sustainable Solutions at CPM, said it’s been a positive for both.

“Their experienced experts offer specialized expertise and knowledge in plastics engineering,” Mayer-Lutz said. “They provide a range of services including consulting, training, research and development, and testing and analysis activities.”

The RingExtruder is also available for compounding requests for sample quantities and many other applications as well, including R&D work or new product development.

For more information on the RingExtruder, visit The RingExtruder RE® : CPM Extricom Extrusion GmbH.